Page 125 - TesaKatalogen

P. 125

D i a l g a u ges – A n a l og u e EN ISO 463

Factory standard

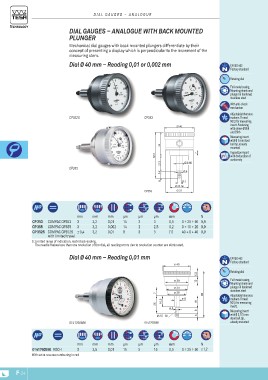

Dial Gauges – Analogue with back mounted Rotating dial

plunger Full-metal casing.

Mounting shank and

Mechanical dial gauges with back mounted plungers differentiate by their plunger in hardened

concept of presenting a display which is perpendicular to the movement of the stainless steel

measuring stem. With anti-shock

mechanism

Dial Ø 40 mm – Reading 0,01 or 0,002 mm Adjustable tolerance

markers. Thread

CP352S CP353 M2,5 for measuring

insert. Fastening

Ø 40 with sleeve Ø 8h6

and 25h6

32 Measuring insert

with Ø 3 mm steel

62.5 7 ball tip, already

mounted

CP355 3.2 21.3 Ø 8 h6 Inspection report

with declaration of

6 Ø4 conformity

CP353 Ø3 EN ISO 463

Ø 25 h6 Factory standard

Rotating dial

Ø 37 Full-metal casing.

Mounting shank and

mm mm mm μm μm μm mm N plunger in hardened

stainless steel

CP 353 COMPAC CP353 3 3,2 0,01 14 3 3 0,5 0 ÷ 25 ÷ 50 0,9 Adjustable tolerance

markers. Thread

CP 355 COMPAC CP355 3 3,2 0,002 14 2 2,5 0,2 0 ÷ 10 ÷ 20 0,9 M2,5 for measuring

insert.

CP 352S COMPAC CP352S ± 0,4 3,2 0,01 9 3 3 (1) 40 ÷ 0 ÷ 40 0,9 Measuring insert

with limited travel with Ø 3,175 mm

steel ball tip,

S: Limited range of indication, restricted reading. already mounted

The needle makes less than one revolution of the dial, all reading errors due to revolution counter are eliminated.

Dial Ø 40 mm – Reading 0,01 mm

ø 40

ø 38 13 6,5

ø 34

ø 2826 7 18

16,5 66

ø8

68

ø4

0141760566

M 2,5 - 6H

0141760566

mm mm mm μm μm μm mm N

15 0,5 0 ÷ 25 ÷ 50 ≤ 1,2

0141760566 ROCH 3 3,5 0,01 15 5

With extra reverse numbering in red

F-24