Page 11 - TesaKatalogen

P. 11

What is known...

Decision Rules for Proving

Conformity or NonConformity

with Specifications

Relationship with the uncertainty of measurement

ISO 14253-1, which is a part of "Geometrical Product Specification GPS", provides "Rules for establi-

shing the conformity or nonconformity with specifications". These rules are valid

for "Inspection by measurements of workpieces and measuring equipment".

This ISO standard makes allowances for the uncertainty of measurement – or more precisely for the

true uncertainty of any measurement whenever the conformity or nonconformity with a given specifi-

cation must be proved. So, for a workpiece, the specification matches a preset tolerance while being

equal to the maximum permissible errors for a metrological characteristic (MPE) for a measuring

instrument.

Any given specification is a constant, whereas the measurement uncertainty is a variable which is

affected by many components. Therefore, the zone of conformity or nonconformity depends on the size

of the effective expanded uncertainty U.

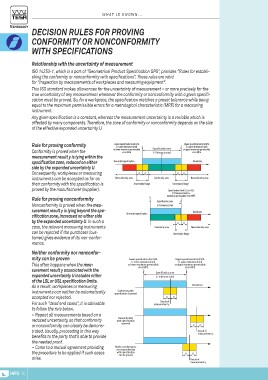

Rule for proving conformity Lower specification limit LSL Specification zone Upper specification limit USL

Conformity is proved when the (= lower tolerance limit) (= Tolera0nce zone) (= upper tolerance limit)

measurement result y is lying within the

specification zone, reduced on either or lower maximum permissible or upper maximum permissible

side by the expanded uncertainty U. error MPE error MPE

Consequently, workpieces or measuring Deviations

instruments can be accepted as far as Two-sided specification

their conformity with the specification is

proved by the manufacturer (supplier). UU UU

Rule for proving nonconformity Nonconformity zone Conformity zone Nonconformity zone

Nonconformity is proved when the mea-

surement result y is lying beyond the spe- Uncertainty Range Uncertainty Range

cification zone, increased on either side

by the expanded uncertainty U. In such a Specification limit LSL or USL

case, the relevant measuring instruments (= Tolerance limit) or

can be rejected if the purchaser (cus-

tomer) gives evidence of its non-confor- 0 maximum permissible error MPE

mance. Specification zone

(= Tolerance zone)

Neither conformity nor nonconfor-

mity can be proven One-sided specification Deviations

This often happens when the mea-

surement result y associated with the UU

expanded uncertainty U includes either

of the LSL or USL specification limits. Conformity zone Nonconformity zone

As a result, workpieces or measuring

instruments can neither be automatic ally Uncertainty Range

accepted nor rejected.

For such "dead end cases", it is advisable Lower specification limit LSL Upper specification limit USL

to follow the rule below. (= lower tolerance limit) (= upper tolerance limit)

– Repeat all measurements based on a

reduced uncertainty, so that conformity or lower maximum permissible or upper maximum permissible

or nonconformity can clearly be demons- error MPE error MPE

trated. Usually, proceeding in this way

benefits to the party that’s able to provide Specification zone

the needed proof. (= Tolerance zone)

– Come to a mutual agreement providing

the procedure to be applied if such cases Deviations

arise.

Conformity with

specification is proved

U U

Result of

measurement y

Nonconformity UU

with specification Result of

measurement y

is proved

Neither conformance UU

nor nonconformity Result of

with specification measurement y

can be proved

INFO-10