Page 12 - TesaKatalogen

P. 12

What is known...

Traceability

to National Standards

All measuring equipment consistently used on our production site is traceable

to national standards or reference fixtures through our quality management

system.

Traceability is established by recalibration at regular intervals with docum entary

evidence as specified in the standards.

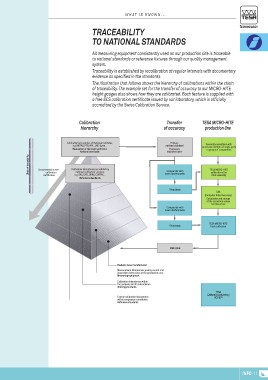

The illustration that follows shows the hierarchy of calibrations within the chain

of traceability. The example set for the transfer of accuracy to our MICRO-HITE

height gauges also shows how they are calibrated. Each f eature is supplied with

a free SCS calibration certificate issued by our laboratory, which is officially

accredited by the Swiss Calibration Service.

Calibration Transfer TESA MICRO-HITE

hierarchy of accuracy prFoedurtcitgiionnglsinlienie

Calibration laboratories of National Institutes, Primary Assembly operations with

e.g. METAS, PTB, NPL, LNE-Syrte... national standard successive controls of single parts

Realization of the metre definition

National standards Frequency or groups of components

stabilised laser

Chain of traceability Documentation over Calibration laboratories accredited by Comparator with TESA MICRO-HITE

calibration national calibration services, laser interferometer calibration after

e.g. SAS, DKD, UKAS, COFRAC... final assembly

certificates Reference standards Step gauge

Comparator with CAA

laser interferometer (Computer Aided Accuracy)

Step gauge Calculation and storage

of the correction values

for bias errors

TESA MICRO-HITE

final calibration

End user TESA

Calibration laboratory

Products to be manufactured

Measurement laboratories, quality control and SCS 001

inspection rooms close to the production area

Measuring equipment

Calibration laboratories within

the company and its subsidiaries

Working standards

Central calibration laboratories

within companies or institutes

Reference standards

INFO-11