Page 317 - TesaKatalogen

P. 317

E le c t r o n i c L e n gth M easu r i n g E q uipme n t

13

8

8

M6 M6

15 5

5 15 30 15 5 38 5 15 30

70 70

FMS 100 FMS 102

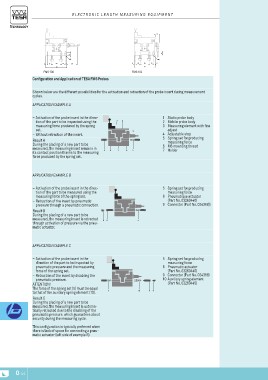

Configuration and Application of TESA FMS Probes

Shown below are the different possibilities for the activation and retraction of the probe insert during measurement

cycles.

Application example A

––Activation of the probe insert in the direc- 72 1 Static probe body

tion of the part to be inspected using the 2 Mobile probe body

measuring force produced by the spring 3 3 Measuring element with fine

set. adjust

4 Adjustable stop

––Without retraction of the insert. 5 Spring set for producing

measuring force

Result A 6 M6 mounting thread

During the placing of a new part to be 7 Holder

measured, the measuring insert remains in

its contact position thanks to the measuring 4 6 1 65

force produced by the spring set.

Application example B

––Activation of the probe insert in the direc- 98 5 Spring set for producing

tion of the part to be measured using the measuring force

measuring force of the spring set. 8 Pneumatique actuator

(Part No. 03260440)

––Retraction of the insert by pneumatic 9 Connector (Part No. 024388))

pressure through a pneumatic connection.

5

Result B

During the placing of a new part to be

measured, the measuring insert is retracted

through activation of pressure via the pneu-

matic actuator.

Application example C

––Activation of the probe insert in the 5 5 Spring set for producing

direction of the part to be inspected by measuring force

pneumatic pressure and the measuring 8 Pneumatic actuator

force of the spring set. (Part No. 03260440)

9 Connector (Part No. 024388)

––Retraction of the insert by disabling the 10 Auxiliary spring element

pneumatic pressure. (Part No. 03260445)

ATTENTION ! 10 8 9

The force of the spring set (5) must be equal

to that of the auxiliary spring element (10).

Result C

During the placing of a new part to be

measured, the measuring insert is automa-

tically retracted due to the disabling of the

pneumatic pressure. which guarantees about

security during the measuring cycle.

This configuration is typically preferred when

there is lack of space for connecting a pneu-

matic actuator (left side of example B).

O-44